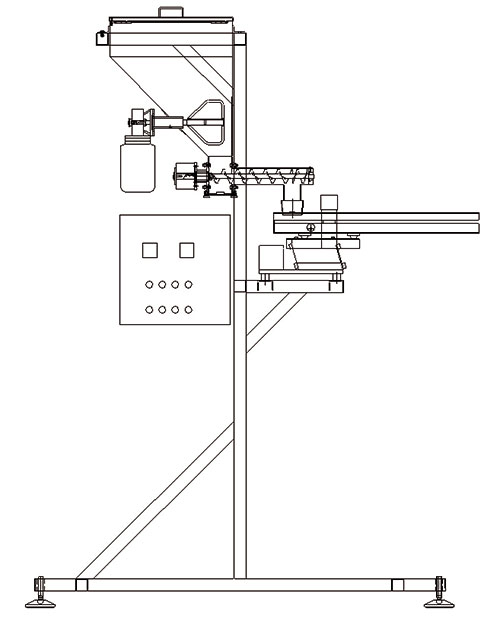

MilkyLAB Dry Salt Device LAB 06

PRODUCTS

Mozzarella, Pizza Cheese, and Analogue Cheese.

TECHNICAL FEATURES

- This system distributes crystalline salt into the cooked flow in a percentage set in proportion to the quantity of product passing

- The cheese previously stretched is conveyed to a slide into the salting station

- The system consists of:

- A volumetric salt feeder including hopper, feeding auger, electronic- control speed drive, lump-crusher, and minimum salt level sensor

- Vibrating tray to guarantee a homogeneous distribution of salt on the product

- A salt feeder tray for homogeneous distribution of salt onto the product

- A flow acquisition unit for determining the quantity of product to be treated

- A PLC for controlling the system, complete with a panel for modifying the working parameters (percentage of salt) and reading the production data

- A support frame

- Feeding group at the forming station

- Structure constructed of AISI 316

- Compression roller rises on the dough

- This system distributes crystalline salt into the cooked flow in a percentage set in proportion to the quantity of product passing

- The system consists of:

- A volumetric salt feeder including hopper, feeding auger, electronic- control speed drive and minimum salt level sensor

- A salt feeder tray for homogeneous distribution of salt onto the product

- Heating salt pipe

- Auger Motor transport salt with inverter to regulate the flow rate

- The machine is supplied with an electrical control panel in Aisi 304 stainless steel/IP65 protection class

- A support frame

TECHNICAL DATA

Hourly Production: 3000 kg / h

Weight: 270 kg

Electric Power: 2 kw

Material: AISI 316 stainless steel

SANITIZATION

The machine is manufactured according to current regulations on hygiene and sanitization.