Automatic Lidding Equipment

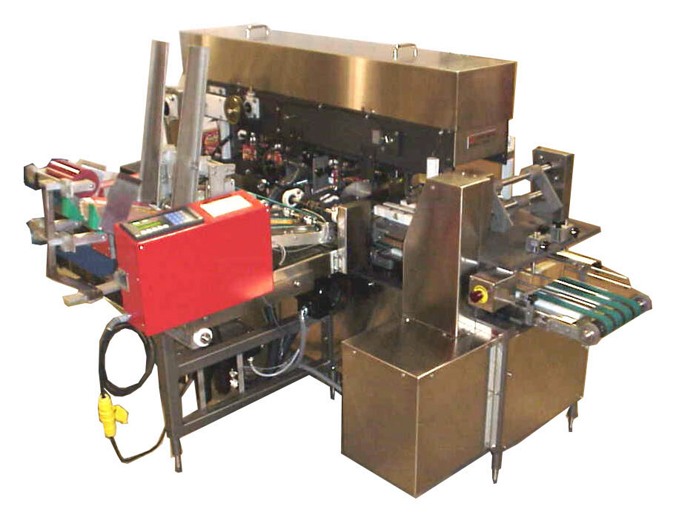

The HART Design & Manufacturing servo-operated lidder automatically forms and applies lids to product filled trays to swiftly and reliably complete your food packaging process.

HART’s lidder is the latest servo-controlled, polished stainless steel equipment. Avoid headaches and downtime. Enjoy the benefits of a customized, robust production line that you can be confident is going to get the job done.

HART uses proven technologies coupled with continual innovation to produce reliable, hygienic equipment to satisfy our clients’ specific processing or packaging requirements.

Servo-Operated Lidder

Streamline Your Filling Process with HART’s Automatic Lidding Equipment

The servo-operated lidder automatically forms and applies lids to product filled trays. A reciprocating pick-and-place assembly picks paperboard lid blanks from the magazines via vacuum cups and places them on reciprocating shuttles. Hot melt adhesive is applied to the lid blank flaps as they are shuttled to the forming section.

Product filled trays are staged on the infeed conveyors and automatically fed into the elevator section. The product trays are elevated and come in contact with glued lid banks and are pushed into the forming sections. The glued lid flaps are folded around trays in the forming section and held in the forming cavities for one machine cycle to allow the hot melt adhesive to solidify. During the next machine cycle lidded packages are elevated out of the forming section and to the discharge conveyor elevation by the upstream packages.

Finished packages are advanced forward by continuous motion sweep arms and transferred onto a single lane discharge conveyor.

Automatic Lidding Features

- Stainless steel sanitary frame construction

- Tool-less quick-change tooling

- Extended 52” magazines