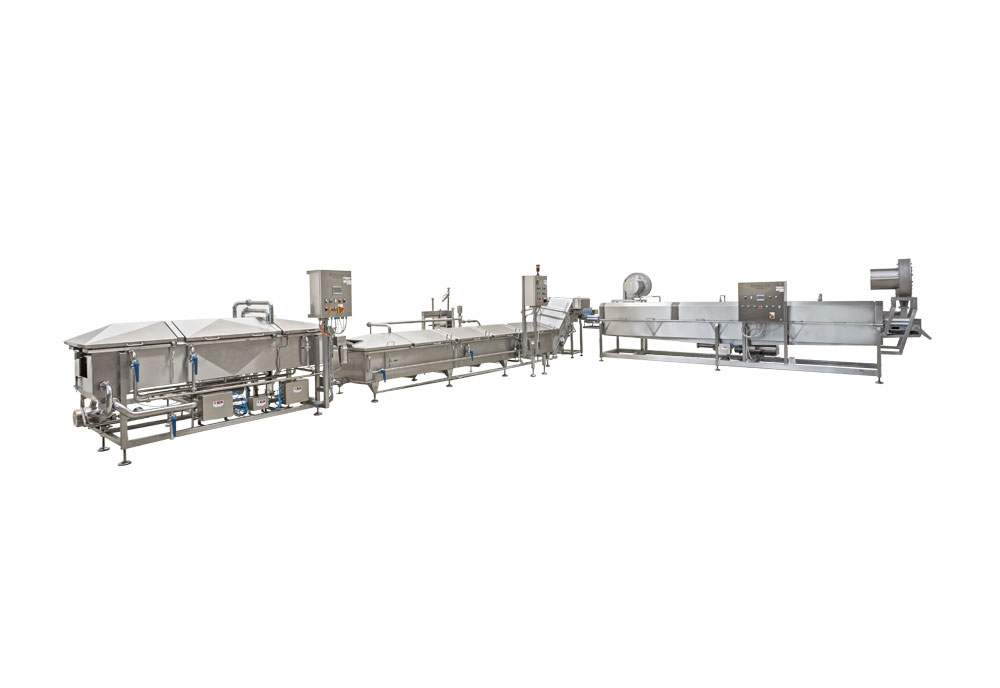

MilkyLAB Drying Tunnel

PRODUCTS

Pizza Cheese, Analogue Mozzarella, Scamorza, and Kashkaval-Kassery.

ADVANTAGES:

- Eliminate excess water on the surface of pasta filata cheeses

- Labor-saving thanks to the automatic drying process

- Preserves the freshness and shelf life of the product

TECHNICAL FEATURES

- Through the drying tunnel, it is possible to eliminate excess water on the surface of pasta filata cheeses.

- Drying has an extremely important function for the quality, freshness, and durability of the product

- Completely built-in AISI 304 stainless steel

- The transport belt is made with material suitable for contact with food products.

- The advancement of the product, at variable speed, is obtained through the movement of the belt-driven by a gear motor with an inverter

- Equipped with 2 separate fans to ensure the airflow from above and below

- Variable-length and width of the tunnel according to the product and the hourly production capacity

- Electric control panel in AISI 304 stainless steel with IP protection 65 equipped with siemens PLC and touch screen for automatic management of the drying phases.

- Safety sensors and protection according to the CEE rules

- sanitization: the machine is manufactured according to current regulations on hygiene and sanitization

- Arrangement to CIP washing system with cover and spraying balls

TECHNICAL DATA

Dimensions: variable lengths and widths

Electric Power: 16 kw

Material: AISI 304 stainless steel

OPTIONAL

Remote assistance.

SANITIZATION

The machine is manufactured according to current regulations on hygiene and sanitization.