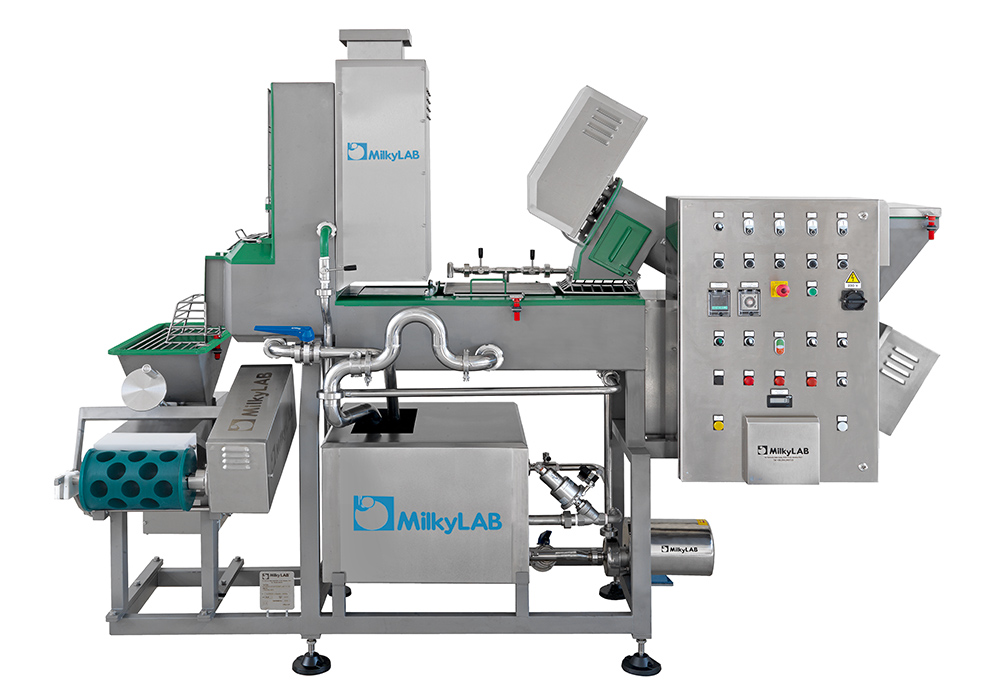

MilkyLAB Compact Machine Mini Cooker-Stretcher – 250/500

PRODUCTS

Mozzarella, Buffalo Mozzarella, Burrata, Cherries, Pizza Cheese, and String Cheese.

ADVANTAGES:

- Traditional production method by hot water

- All-in-one stretching and molding unit

- Continuous stretching production process by hot water injection

- Cooking section with N. 2 contra-rotating augers

- Kneading section with N. 2 kneading arms

TECHNICAL FEATURES

- Entirely built in AISI 304 stainless steel

- All-in-one stretching and molding machine

- Cooking vat with 2 variable-speed augers by inverter

- The kneading section is equipped with 2 kneading arms, moving with variable speed by inverter, allow the product to acquire the desired structure

- Hot water prepared composed of electro pump for circulating the water, pneumatic steam on-off valve, automatic temperature regulator

- The molding vat is equipped by 2 augers and N. 1 molding roller

- The molding roller and the augers have adjustable speed by Inverter

- Parts that encounter the product are shot-peened with quartz microspheres and the augers feature Teflon coating

- Electrical control panel built-in AISI 304 stainless steel with IP 65 protection

- Thermoregulatorwith digital display for temperature control

- Safety sensors according to the CEE regulations

TECHNICAL DATA

AVAILABLE MODELS

Hourly Production: 250 kg / h

Dimensions: 290 x 100 x 210 h cm

Weight: 600 kg

Electric Power: 6 kw

Material: AISI 304 stainless steel

MOLDING ROLLER AVAILABLE

- Mozzarella balls: from 1 to 200 g

- Scamorza up to 300 g

- Cylindrical or rectangular blocks up to 3 kg

- String cheese and spaghetti cheese

- Conveyor for continuous cords

OPTIONAL

Arrangement to CIP washing system with cover and spraying balls.

SANITIZATION

The machine is manufactured according to current regulations on hygiene and sanitization.