MilkyLAB Compact Machine

PRODUCTS

Mozzarella, Buffalo Mozzarella, Pizza Cheese, Kashkaval, Analogue Mozzarella, Processed, and Spread Cheese.

It is suitable for processing fresh and industrial blocks of curd, buffalo curd, powders, rennet casein, starch, and vegetable or animal fat.

ADVANTAGES:

- Thanks to the electrical steam generator and small sizes, can be placed in university,

- R&D laboratories, supermarkets, and farms

- Possibility to use fresh and industrial curd, powders ingredients, spices, and flavors

- More production yield than the traditional systems by hot water

- Stretching by direct steam injection in the product or into the jacket

- Reduction of heating and stretching time thanks to the steam injection

- Significant energy saving by reducing steam consumption

- Standardization of moisture in the final product

TECHNICAL FEATURES

- Entirely built in AISI 304 stainless steel, double-wall vat for the steam injection into the jacket

- All-in-one stretching/molding machine for small level production(from 5-20kg/batch) and suitable for R & D laboratories and University

- The machine is equipped with an incorporated electrical steam generator(Italian Patent) that can produce the necessary quantity of steam during the stretching phase

- There will not be more fatty liquid to be purified as all water added is absorbed by the product during steam stretching

- Product stretching is performed either by steam injection, direct into the product, or in the double jacket

- The stretching vat is equipped by 2 bi-directional augers, with adjustable speed by Inverter

- Thermoregulatorwith digital display for temperature control

- The molding vat is equipped by 2 augers and N. 1 molding roller

- Jacket that keeps the product at the ideal molding temperature

- The molding roller and the augers have adjustable speed by Inverter

- Parts that come into contact with the product are shot-peened with quartz microspheres and the augers feature Teflon coating

- Electrical control panel equipped by a “touch screen” operator panel and PLCfrom which it is possible to control the different stretching – molding process phases

TECHNICAL DATA

Hourly Production: 80 kg / h, 5-20 kg / batch

Dimensions: 120 x 80 x 155 h cm

Weight: 320 kg

Electric Power:

12,5 kw (version with electric steam generator)

2,5 kw (version without electric steam generator)Material: AISI 304 stainless steel

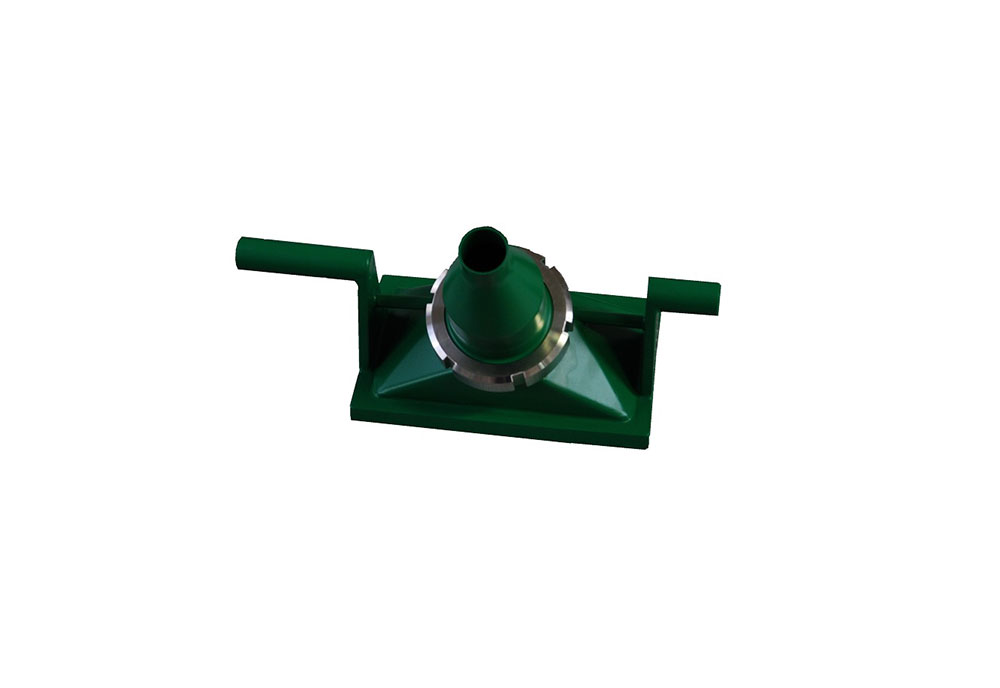

MOLDING ROLLER AVAILABLE

- Mozzarella in balls: from 1 to 200 g

- Scamorze up to 300 g

- Cylindrical or rectangular block up to 1000 g

- String cheese and spaghetti cheese

- Conveyor for continuous cords and nodding

OPTIONAL

Remote assistance by internet.

SANITIZATION

The machine is manufactured according to current regulations on hygiene and sanitization.