SOS-ESL Electrostatic Sprayer for Lecithin

HART Design & Manufacturing’s Electrostatic Sprayer for Lecithin is engineered for precise, consistent oil application with minimal waste. Ideal for continuous production lines, this in-line system delivers a uniform, electrostatically charged spray that adheres directly to grounded surfaces for superior coating performance.

- Repeatable, Consistent Lecithin Application

- Effectively Manage Line Speed Changes (opt. sensor for line speed reference signal)

- Accurate, Superior Quality (uniform, precise coating)

- Improved Performance, Virtually Zero Waste (charged oil targets the grounded surface

Built for reliability and efficiency, the SOS-ESL helps maximize yield and product quality—while adapting to your production environment.

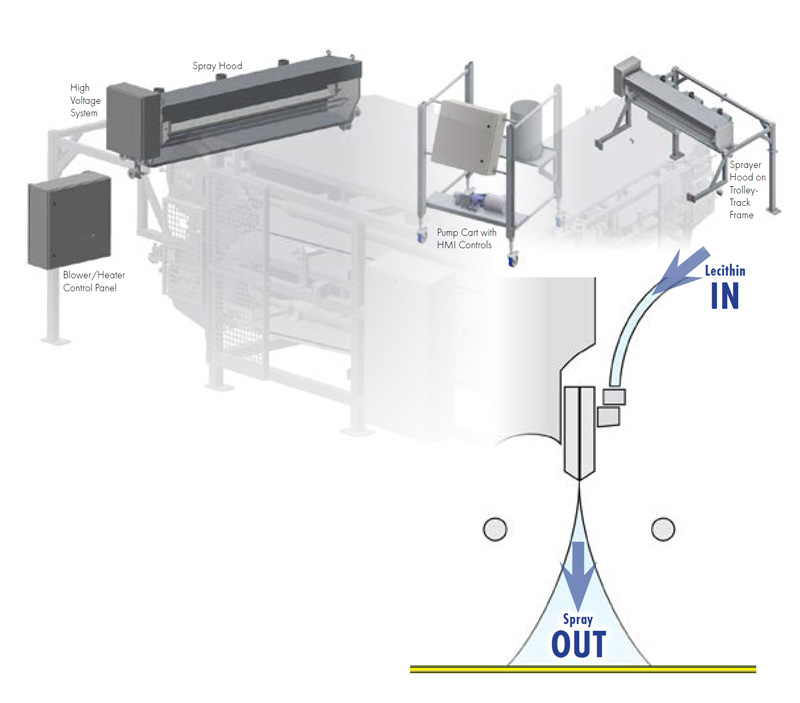

Precision Spraying Action

These electro-hydrodynamic coating machines apply voltage to the Lecithin, charging the oil and propelling it from the nozzle. A uniform, precision coating is created when the electrostatically charged droplets target the grounded surface.

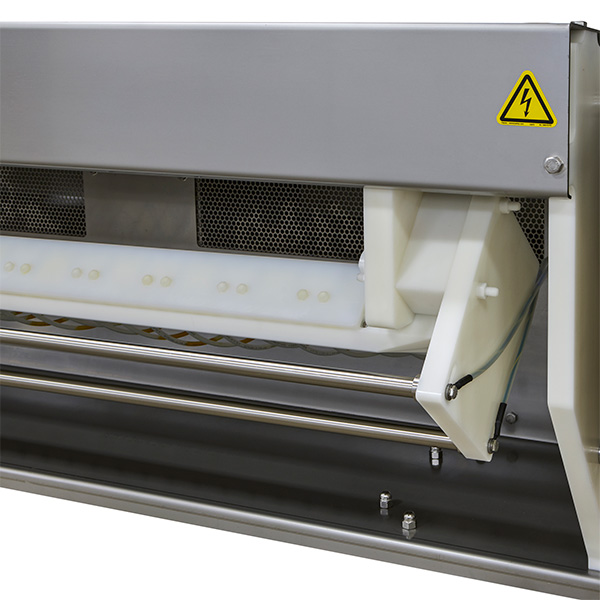

The ESL model Electrostatic Sprayer is an automatic, in-line system which is typically integrated onto the back end of a casting line; it atomizes Lecithin which it applies to the target product in a tightly controlled formation with virtually zero waste.

Maximize Yield

Experience less waste as the atomized, charged spray precisely targets the grounded surface. No mechanical force is used to produce the spray pattern – so over-spray and misting are minimized.

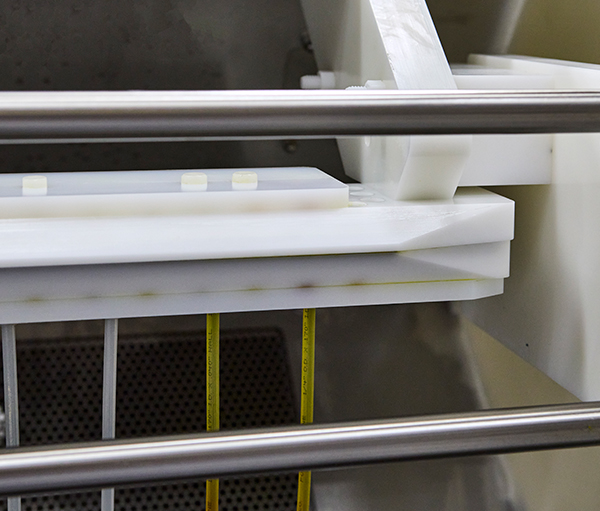

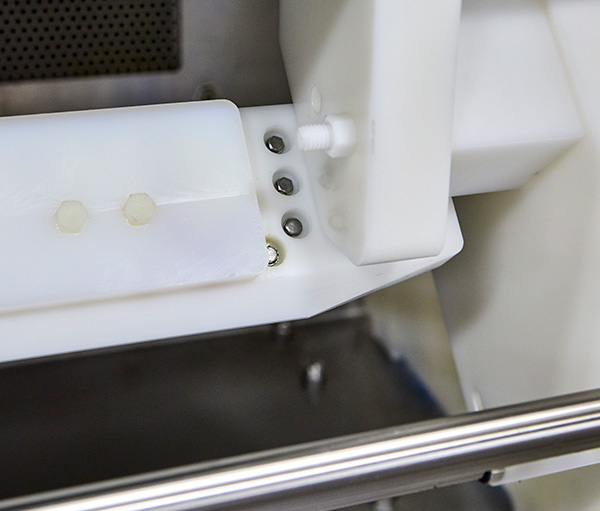

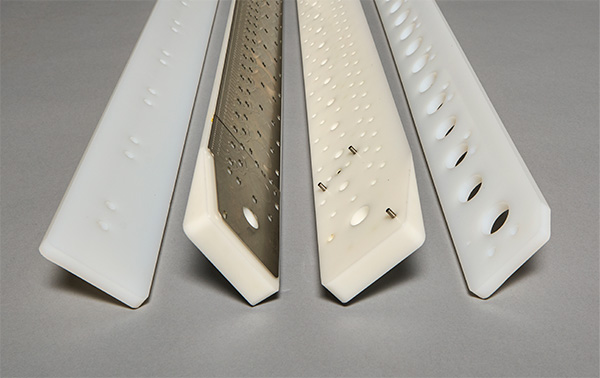

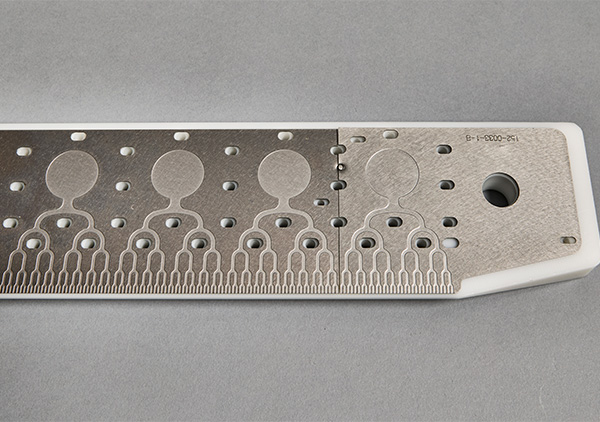

The nozzle is made of non-conductive plastic and encapsulates a stainless steel “spray plate” that acts as a metering device and an electrode. Uniform, precise droplets are generated by charging the fluid as it enters the nozzle cavity, passing over the electrode (high voltage DC). The fluid is instantly charged, attracted to the intended product. The charged droplets seek out and adhere to the grounded surface, creating an extremely uniform and controllable coating.

Easy, Accurate Operation

Technical Data

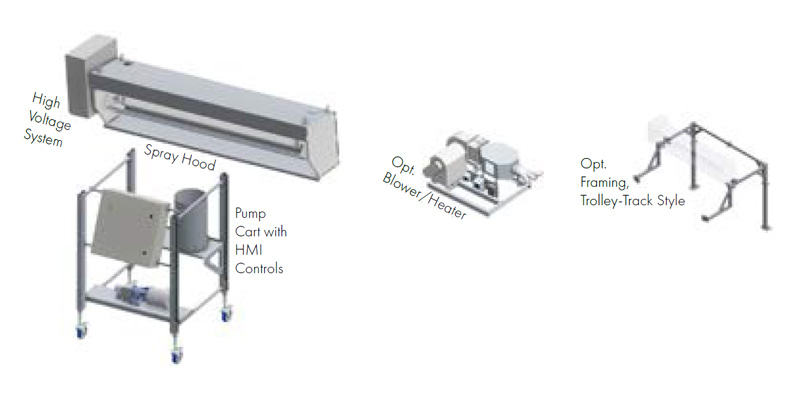

Accessories & Alternative Solutions

Trust HART Automation

Automatic spraying system is equipped with standard safety features, including an emergency stop button.

Included Functions

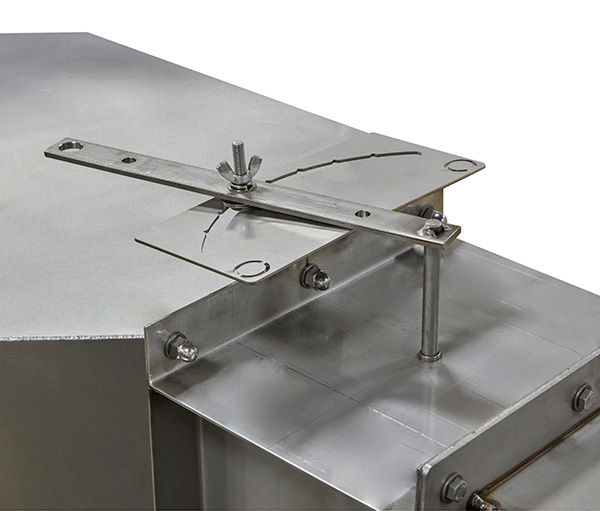

Sprayer, High Voltage System, Pump Cart, Optional Framing / Integration, and Optional Blower / Heater Skid.