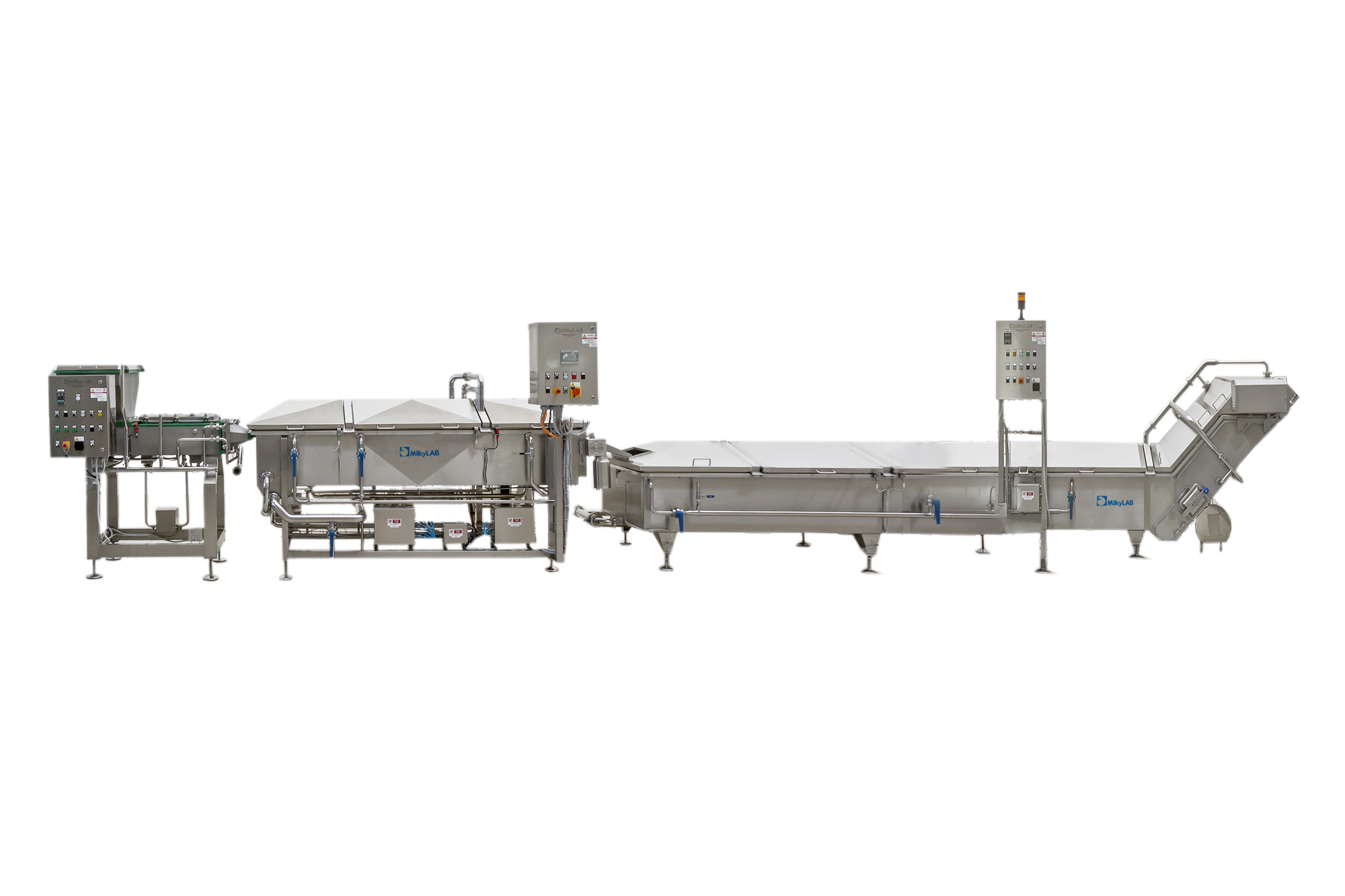

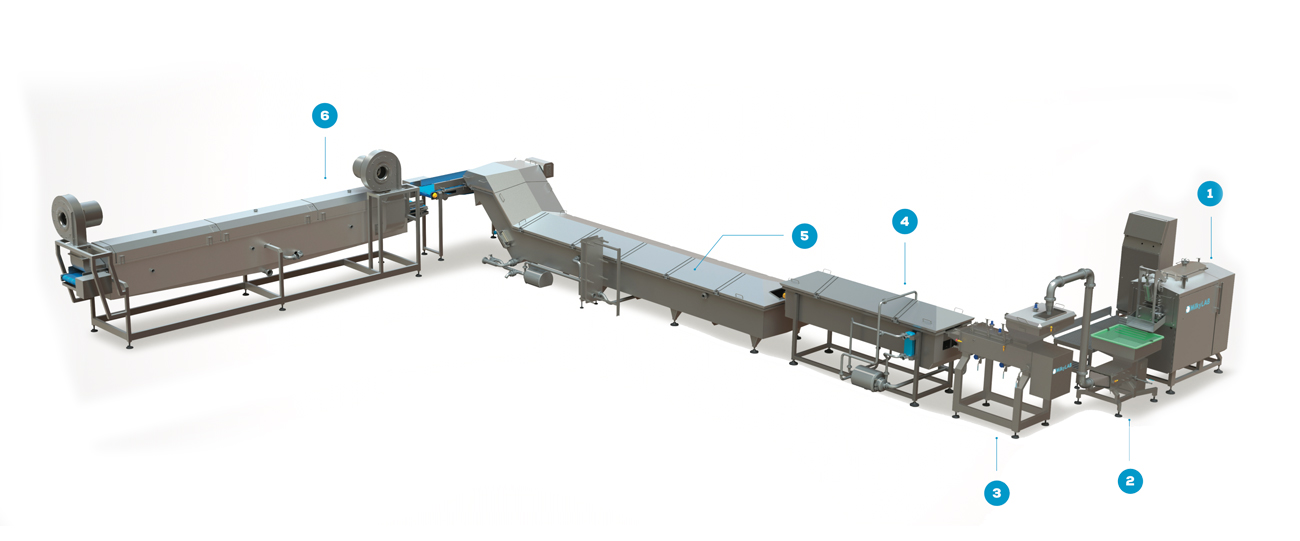

MilkyLAB String Cheese Production Line

- Steam Melter-Stretcher

- Feeding Machine

- Extruders

- Pre-Cooling and Cutting System

- Brine Vat

- Drying Tunnel

The string cheese automatic production system is composed of a Steam cooker-stretcher (1) with a direct introduction or through 4 bar double jacket and with an attached feeding machine (2) towards the automatic molding machine equipped with an exclusive extrusion system (3). The final product is introduced into the automatic pre-cooling and cutting system (4).

The final phases involve the passage in brine vats (5) and then in the drying tunnel (6).

Our customers, by using this system can produce string cheese by choosing the desired diameter and variable lengths.

The system is completely made in AISI 304/316 stainless steel and it is totally arranged for the CIP automatic washing system.

The size and features can be customized based on customer requirements.