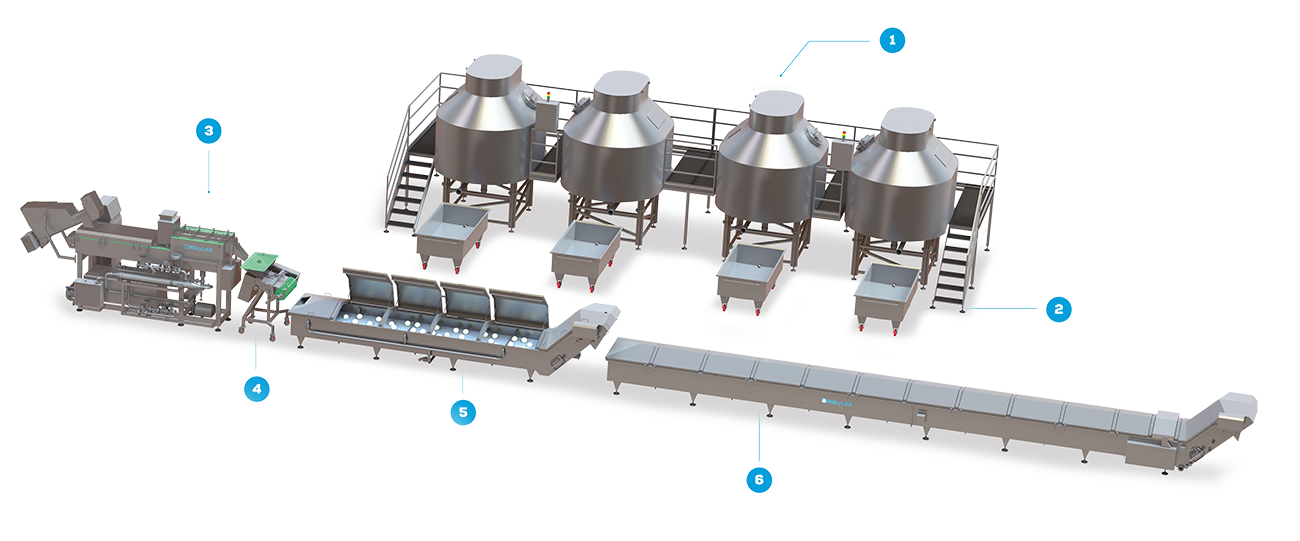

MilkyLAB Spherical Mozzarella Production Line

- Cheese Vats

- Drainage Truck

- Hot Water Cooker-Stretcher

- Molding Machines

- Pre-Cooling Vat

- Cooling and Drying Solutions

The automatic spherical mozzarella production system is a turnkey solution that begins with the coagulation of milk until the product is ready for packaging. The system shown includes 4 double “0” cheese vat machines (1), essential if one chooses to start with milk as a raw material. The functions, in this first phase of the production process, are milk coagulation and curd maturation. The curd is then discharged into the appropriate drainage trucks (2) and after reaching the right pH of maturation it is introduced into the cooker-stretcher machine (3). The stretched cheese will be formed by the special molding roller machine (4), which in cascade introduces the mozzarella into the pre-cooling (5) and cooling (6) vats.

The system is completely made in AISI 304/316 stainless steel and is completely arranged for the CIP automatic washing system.

The size and features can be personalized based on customer requirements.