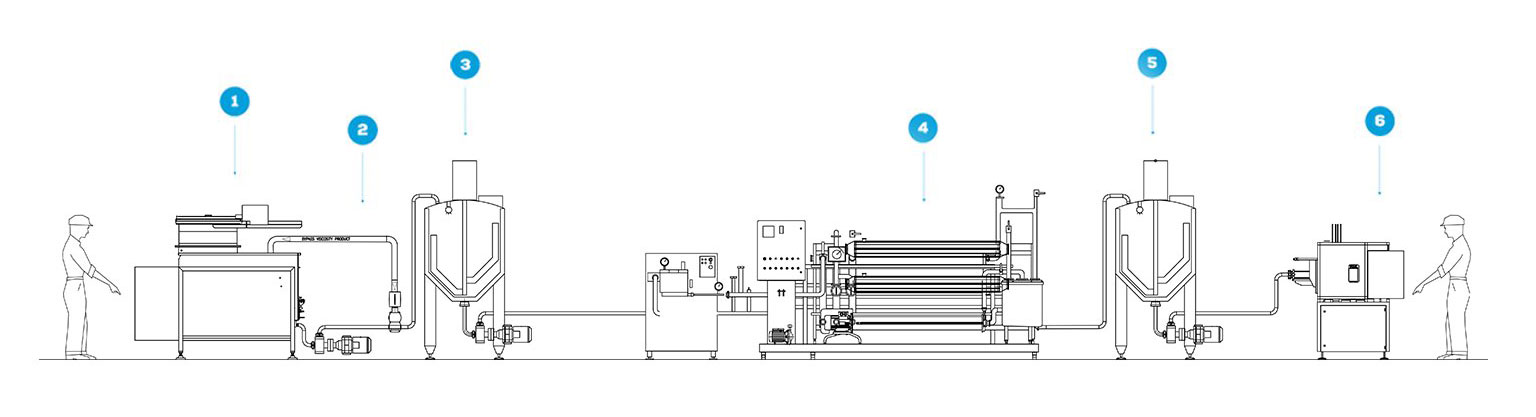

MilkyLAB Processed Cheese Production Line

- Melters

- Homogeniser

- Tank

- UHT System

- Tank

- Packing Machine

The automatic processed cheese plant responds to the growing market demand for melted and spreadable cheeses and thanks to MilkyLAB technology it can produce even without milk, using raw materials such as whey powders, animal or vegetable fats, emulsifying salt, spices, and flavors.

The system shown includes the steam cooker (1), characterized by the exclusive steam technology with direct injection or through a 4-bar double jacket.

Subsequently the product, through the pump (2) is introduced into the special storage tank (3) and then passes into the UHT system to guarantee maximum food safety. In the final part, the product is packaged.

Considerable savings in time, labor, and energy consumption are achieved with the automatic analogue mozzarella production plant.

The system is completely built-in AISI 304/316 stainless steel and is totally arranged for the CIP automatic washing system.

The size and features can be personalized based on the customer’s requirements.