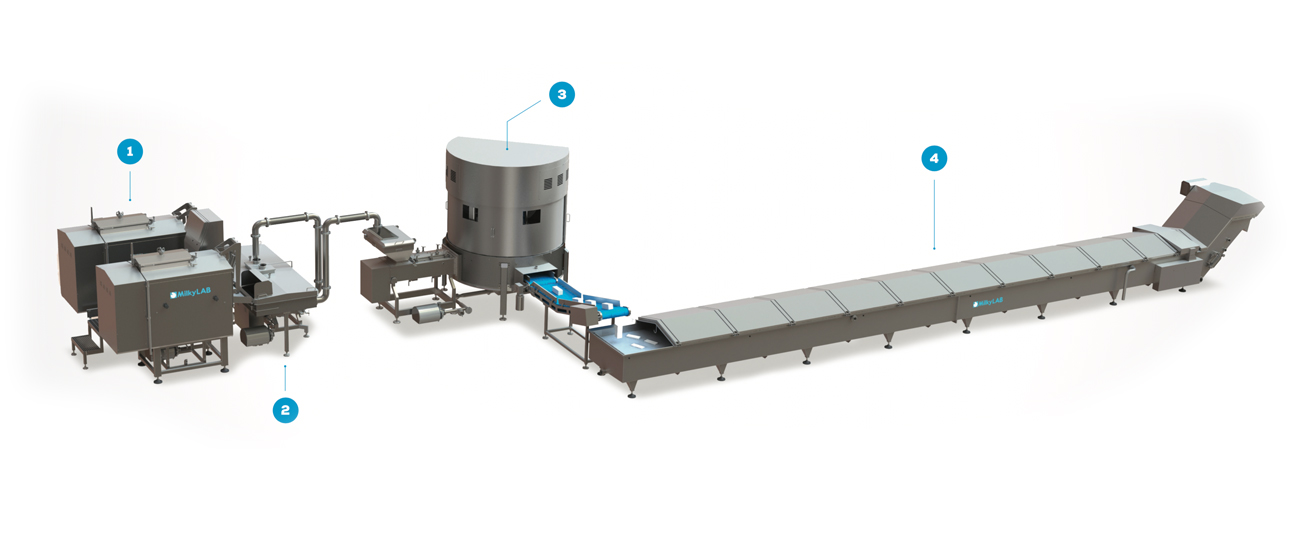

MilkyLAB Automatic Pizza Cheese Production Line

- Steam Melter-Stretcher

- Feeding Machine

- Molding Machines

- Cooling and Drying Solutions

The automatic pizza cheese production plant is an innovative solution that combines stretching with steam technology and automatic molding in a complete production process. It is particularly suitable for medium-large productions (up to 3.000 kg/hour). The process begins with the steam cooker (1), through the exclusive steam technology with a direct introduction, or through 4 bar double jacket. Subsequently, the product, through the augers feeding machine (2), is introduced into the automatic carousel molding machine (3), which makes the production process continuous.

In the final process phase, feeding occurs via an automatic variable speed cooling vat (4). A considerable saving in time, labor, and the energy consumption is achieved with the automatic pizza cheese production plant.

The system is completely made in AISI 304/316 stainless steel and it is totally arranged for the CIP automatic washing system.

The size and features can be personalized based on customer requirements.