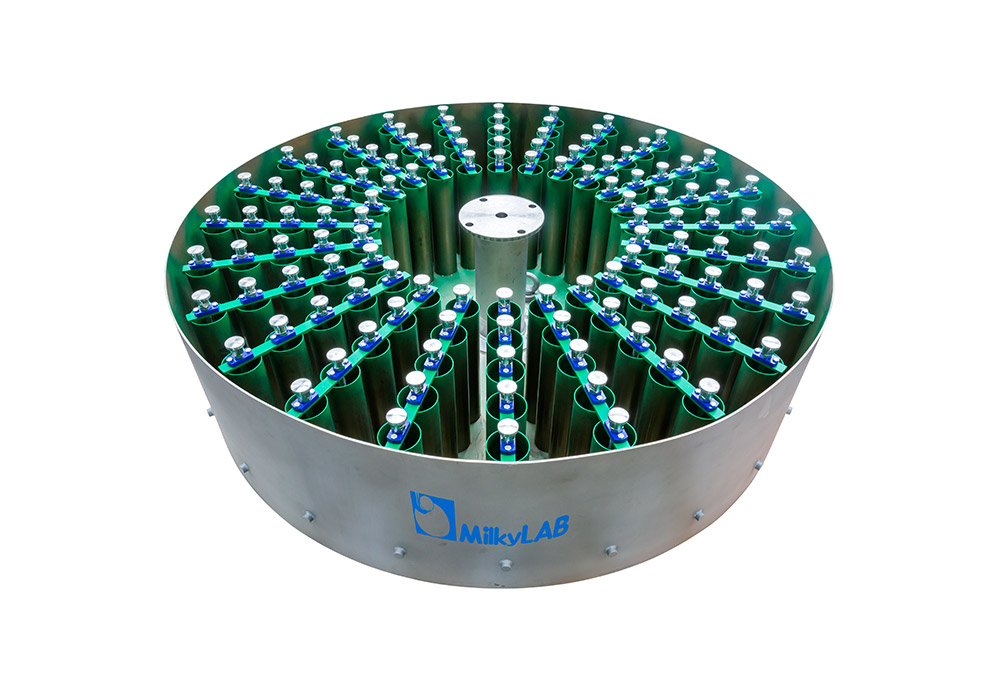

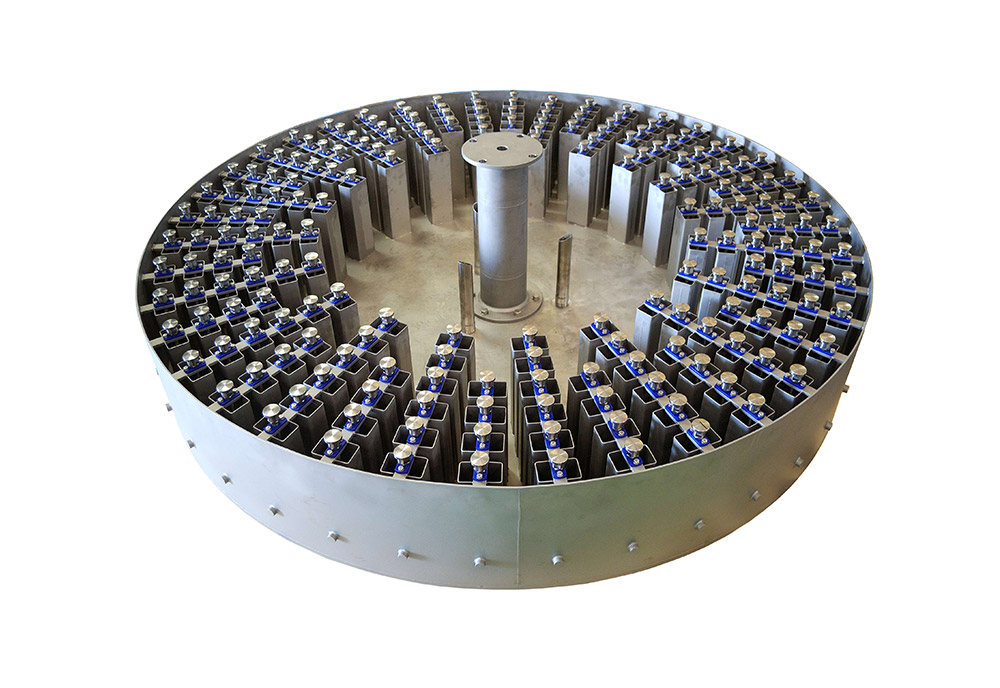

MilkyLAB Molding Machine LAB 29 CIP Carousel

PRODUCTS

Kasar, Mozzarella for Pizza, Blocks in cylindrical or rectangular shapes, Kashkaval, and Kasseri.

ADVANTAGES:

- Automatic molding and pre-cooling for cylindrical or rectangular shapes

- Reduction of production time and labor costs

- Pre-cooling treatments in the molding head by the circulation of cold water outside the molding pipes to avoid the contamination in the product

- Easy to change the molding head

TECHNICAL FEATURES

- Entirely constructed in AISI 304 stainless steel or AISI 316 L optional

- The electrically heated jacket allows the product to be kept constantly at the ideal molding temperature

- Molding and the pre-cooling head is complete with cylindrical or rectangular shape molds with continuous rotation and with variable speed by inverter

- Cooling happens by means of the cold-water circulation outside the molding pipes to avoid any contamination, ensured by a self-priming pump and a plate heat exchanger

- Arrangement for CIP washing in the molding head: the machine is totally closed with an integral cover which permits the automatic washing system with spraying balls

- To make the washing easier on the bottom of the molding pipes, the molding head is lifted by a pneumatic system and internal spraying balls wash completely the molding head

- Electronic regulation of the height of the product

- Automatic control of the cooling temperature and the rotating speed of the molding head, which determines the cooling time and the hourly production

- Product expulsion on the conveyor system which discharges the product directly into the RF automatic cooling line

- All the parts in contact with the product are entirely shot-peened with quartz microspheres or Teflon-coated in order to be non-stick

- Electrical control panel in AISI 304 stainless steel with IP 65 protection equipped by a “touch screen” operator panel and PLC Siemens

- Electrical panel is equipped with remote-assistance

- Safety sensors according to the CEE regulations

TECHNICAL DATA

AVAILABLE MODELS

Hourly Output: 1600 kg / h

Dimensions: 265 x 180 x 240 h cm

Electric Power: 9,5 kw

Molding Head Diameter: 160 cm

ACCESSORIES

- Head transportation trolley

- Canala for directly discharge in the brining or cooling vat

POSSIBLE ADJUSTMENTS

- Rotating speed of molding head

- Auger’s speed

- The weight of the product by the regulation of the filling height

- Temperature of the cooling water with plate heat exchanger

SANITIZATION

The machine is manufactured according to current regulations on hygiene and sanitization.