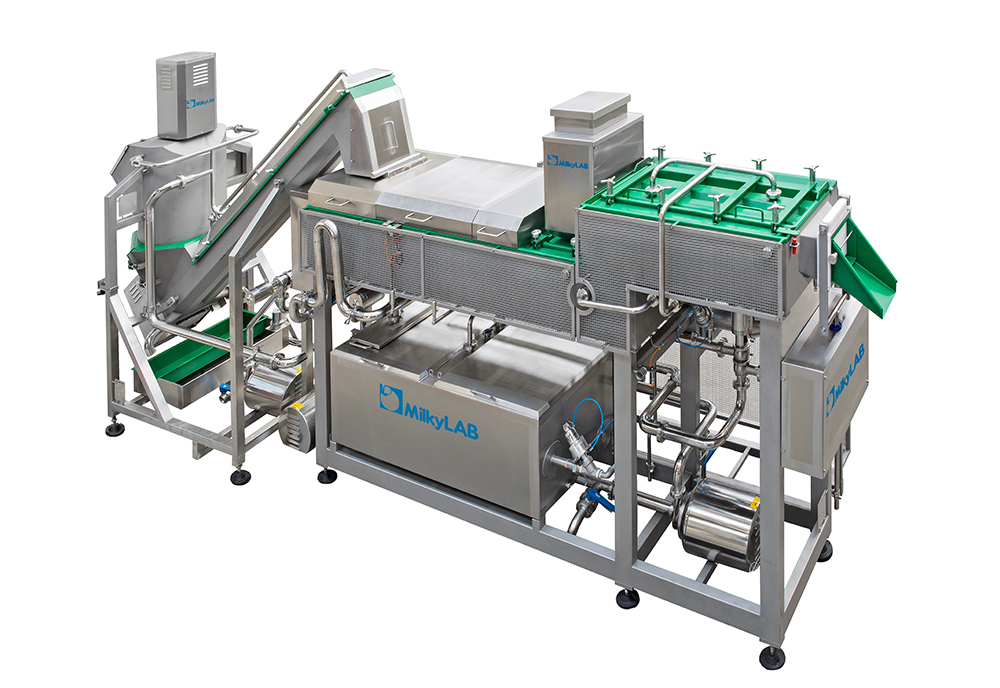

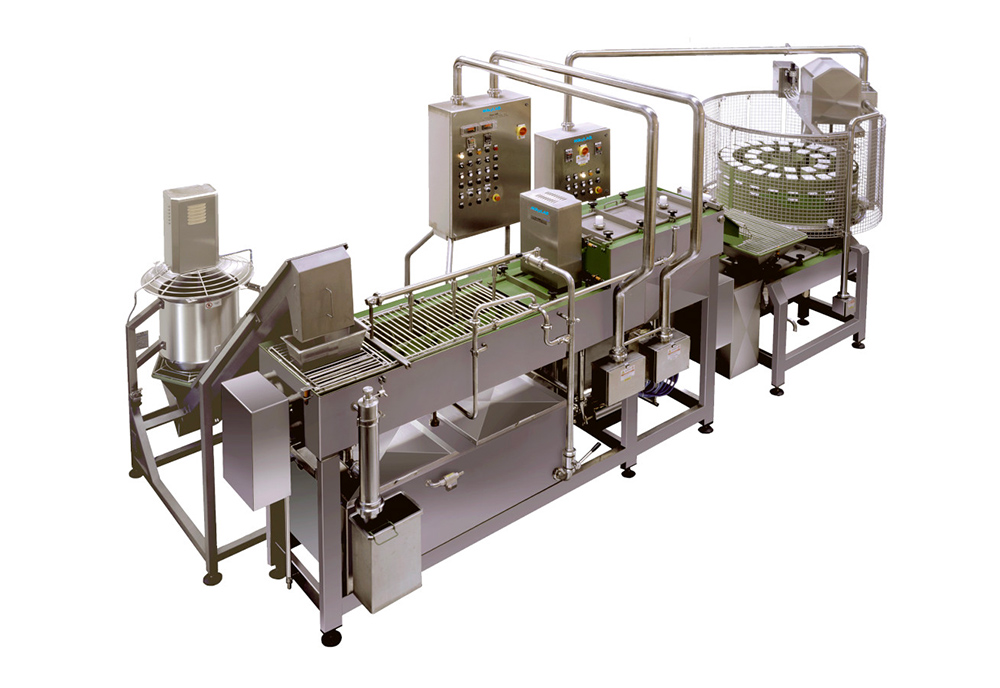

MilkyLAB Hot Water Cooker-Stretcher LAB 2500 – LAB 5000

PRODUCTS

Kasar, Mozzarella, Buffalo Mozzarella, and Pizza Cheese.

ADVANTAGES:

- It has the function of cooking, stretching and kneading any type of stretched-curd cheese, with medium-low moisture content and a compact structure

- The product stretching happens by hot water, by steam or both

- It is particularly suitable for those systems with a high hourly output

- Continuous stretching production process

- It’s possible to reach extremely interesting yields and reduce process losses to a minimum

- Final stretching phase with kneading arms or with paddle

TECHNICAL FEATURES

- Entirely built in AISI 304 stainless steel. AISI 316 L optional

- The stretching can happen by hot water in the first section, and by steam in the second section or both

- The first stretching section with 2 variable-speed augers by inverter and the second stretching section is located at a higher level to enable the excess water to be drained

- System for circulating the cooking water, complete with plate heat exchanger and temperature control

- Equipped with a high-capacity hot water preparatory tank and an electro pump to expel the whey

- Electric control panel to manage with the automatic recipe all cooking/stretching phases by PLC Siemens and remote-assistance

- All the parts in contact with the product are entirely shot-peened with quartz microspheres or Teflon-coated in order to be non-stick

- Furthermore, the special dimensioning of the cooking section of the Lab 2500 makes it possible to operate with very low water temperatures, so as to reach extremely interesting yields and reduce process losses to a minimum

- This is also allowed by the jacket, which is provided with its own heating system and independent regulation of its temperature

- Arrangement to CIP washing system with cover and spraying balls

TECHNICAL DATA

AVAILABLE MODELS

-

Hourly Production: 2.500 kg / h

Dimensions: 325 x 110 x 210 h cm

Weight: 860 kg

Feed Height: 143 cm

Output Height: 145 cm

Electric Power: 12 kw

Steam Consumption: 300-600 kg / h

ACCESSORIES

- Hot water preparation unit consisting of a tubular water- steam exchanger with a high exchange surface

- Real product temperature control sensor

SANITIZATION

The machine is manufactured according to current regulations on hygiene and sanitization.