Filling Equipment

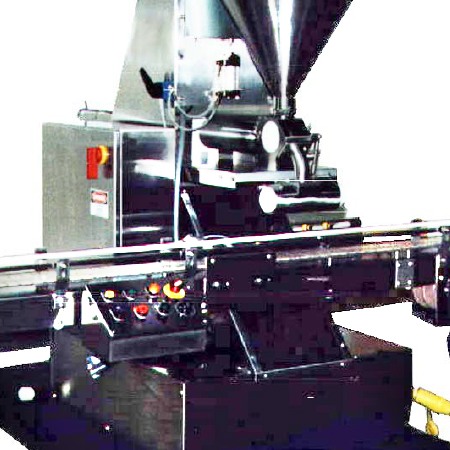

Package your cream cheese, process cheese, or other food products more reliably and less expensively with the latest servo-controlled, polished stainless steel filling equipment from HART Design & Manufacturing. Avoid headaches and downtime. Enjoy the benefits of a customized, robust production line that you can be confident is going to get the job done.

HART uses proven technologies coupled with continual innovation to produce reliable, hygienic filling equipment to satisfy your specific processing or packaging requirements.

HART’s Filling Products

Improve the Speed and Reliability of Your Cream Cheese or Process Cheese Line with HART Filling Equipment

HART is best known for the quality and reliability of its cheese filling equipment. Following is a description of how our filling products work.

Carton-formers / erectors are used for cartoned packages, whereas pouches are inserted into stainless cavities if a soft pack is desired.

A carton-former erects a pre-cut cardboard blank into the particular form of the carton to be used. The HART packaging line can fill a one-piece or two-piece carton style. The formed carton is then conveyed to the infeed of the filling line. If the carton is a one-piece style, the scores are creased on an alternate infeed section.

The erected cartons then move on to the carton creaser section. Cartons are fed into the pusher lugs of the carton creaser automatically. As the cartons are indexed, flaps are folded down and held in such a position. The pusher lugs carry the cartons through the carton creaser and discharges them, with flaps down, into the carrier pockets of the indexing conveyor.

The auto-pouch section of the filling line forms a pouch from roll stock material by running it through a series of dancer rolls, forming board, and nose piece to ultimately make a gusseted bottom pouch of proper size.

The roll stock film has a maximum diameter of 24 inches with a core diameter of 6 inches. A powered unwind unit pulls the film web from the rolls. An optional servo web aligner guides the film through a set of stationary and dancer rollers into the forming board. Prior to the pouch forming board the edge is turned over to provide an “easy opening” feature. The turned over edge also adds rigidity to the pouch which enables the pouch to be more erect in the carton.

Side seal bars section off the film web into individual pouches. Servo driven nip rolls pull the pouches into the opener / inserter section. As a pouch is fed out over the opener / inserter it is held by a set of vacuum jaws. The pouch is then cut by a shear knife and opened by servo-driven vacuum boxes. An expanding mandrel then enters the opened pouch and inserts it into a carton. The pouch assumes a perfectly formed rectangular bottom, exactly duplicating the inside dimensions of the formed carton. The pouch has no creases or film wrinkles to mar the display appearance. The inserted pouches remain erect in all four corners of the carton.

The auto-pouch section is PLC controlled and has the capability to run registered or unregistered film. The pouchmaker section has a no carton / no pouch feature. Defective pouches or cartons are detected and rejected prior to the filling system.

Distinct Auto-Pouch Assemblies

Each core shaft has a roll side adjustment that is used to move the film roll to achieve top edge evenness.

Distinct Filler Assemblies

The cartons are pushed into the conveyor section by means of line pressure on the continuous conveyor. A backlog eye stops carton from feeding. A gate opens upon a signal from the filler. A carton is released into the filler conveyor section.